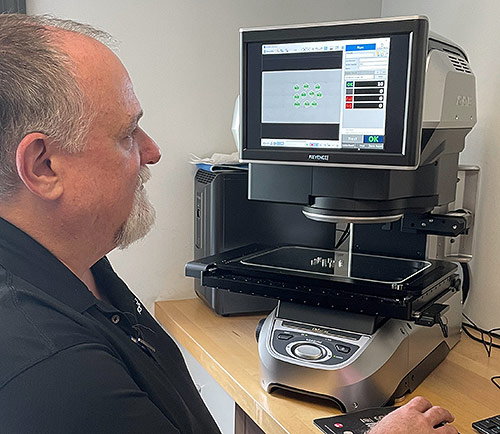

New Keyence Image Dimension Measurement System

Meet the newest member of our quality team!

We purchased this Keyence IM-8000 Series Image Dimension Measurement System in February. It has immediately impacted our quality control and production processes, enhancing our ability to ensure that every part we deliver exceeds acceptable tolerances.

The predictive data provided by the IM-8000 allows us to identify trends that will help prevent the production of nonconforming parts. The system also alerts us when dimensions approach acceptable tolerances so that our production team can make adjustments before running parts.

After our quality team enters your part’s specifications and measurements from CAD drawings, the IM-8000 can scan up to 30 pieces at a time, creating a 360-degree video image to compare to the specifications on file. It records critical dimensional data and nonconforming part counts to the part file.

This new equipment checks parts far quicker than our traditional optical comparator system and provides comprehensive first-article inspections. Both quality and production employees use the Keyence machine for part checks throughout the day.

In addition to reducing the number of nonconforming parts produced, we have experienced less machine downtime, created less material waste, and scrapped fewer parts, easing unnecessary stress on our employees – and making it easier for us to deliver the high-quality parts you have come to expect from Fourslide!