Facility Upgrade Continues

After a 20-month hiatus – both scheduled and dictated by COVID protocols – the next phase of our facility update and reorganization is back in full swing.

The first stage of upgrades intended to boost production capacity by as much as 50% involved relocating our toolroom to an up-fitted area previously vacated by our assembly operation. This new phase involves the area that previously housed our toolmaking activities.

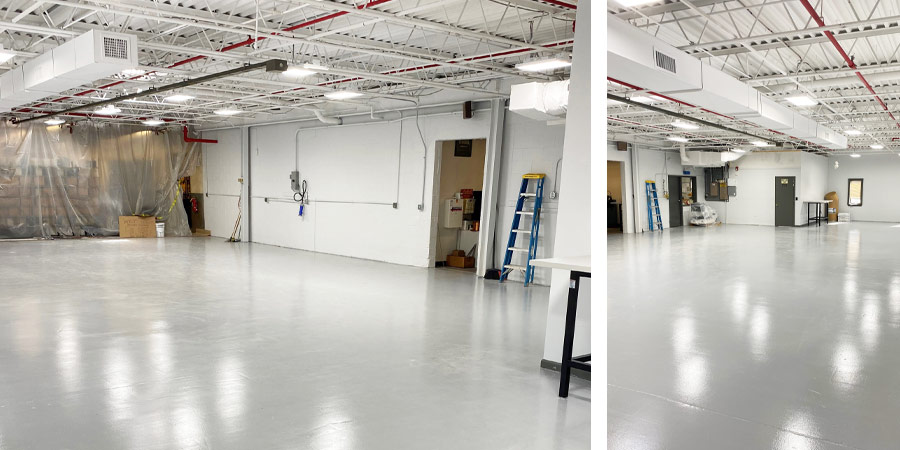

The area was cleaned thoroughly; floors sanded, patched, and painted; walls and ceiling painted; and fluorescent lighting upgraded with LED lighting. A wall that previously separated the EDM machines and CAD area from the greater toolroom was also removed. Finally, we’ve freshened up our break room with sheetrock, paint, a new drop ceiling, LED lighting, cabinets, and blinds.

Once complete, the refreshed area will accommodate an expansion of our production department. We are regularly acquiring fourslide machines, and shoehorning them into our plant has been a challenge. This reorganization opens up an additional 2,500 square feet of production space, which will grow into 4,000 square feet as we continue with the project in the coming months.

The space that once housed our tool room, which was relocated and updated in 2019.

The space was completely refurbished to create an additional 2,500 square feet of production space.

Newly renovated space for our expanded production department.